5 Essential Dust Collection Systems Every Manufacturer Needs in 2025

The Importance of Dust Collection

Effective dust control is essential to prevent serious health concerns, fire hazards, and costly penalties from OSHA violations. In food production environments, systems designed for collecting flour and grain dust are vital for preventing cross-contamination and enhancing indoor air quality. In sectors such as woodworking and metal fabrication, workshop dust filtration systems help maintain cleanliness and prolong the lifespan of equipment.

Common Types of Dust Collection Systems

Cyclone Dust Collectors

Cyclone dust collectors are well-suited for heavy-duty tasks in woodworking and metalworking environments. By using centrifugal force, they remove large dust particles before the air reaches the filter. This pre-separation step reduces the frequency of filter maintenance and increases system efficiency.

Cartridge Dust Collectors

Ideal for food processing plants, cartridge dust collectors are frequently used for managing flour dust. These systems are equipped with filters that capture fine particles efficiently and are designed for easy cleaning, making them a hygienic and convenient solution.

Centralized Factory Dust Collectors

For large-scale industrial operations, centralized dust collection systems provide continuous performance through pulse-jet cleaning technology. These systems are optimal for handling high volumes of dust and reducing downtime.

Selecting the Right System

Choosing an appropriate dust collection system depends on factors such as industry type, facility size, and dust characteristics. Food manufacturers should prioritize grain dust systems with explosion-proof features, while facilities focused on metal or woodwork may find powder dust collectors more effective.

Maintenance and Regulatory Compliance

Routine maintenance is essential for both performance and compliance with OSHA requirements. Best practices include:

Regularly checking airflow to prevent clogs.

Replacing filters before they become saturated.

Inspecting and cleaning ductwork to remove built-up debris.

Maintaining accurate records to demonstrate compliance during audits.

Many modern systems now incorporate smart technology that allows real-time monitoring and sends maintenance alerts to operators.

Technological Advances in Dust Collection

Recent innovations are improving the safety and efficiency of dust collection systems. Today’s grain dust collection units often include IoT connectivity for live system updates, self-cleaning filters that reduce upkeep, and integrated fire suppression features to mitigate explosion risks.

Conclusion

Installing a reliable dust collection system is essential for workplace safety, regulatory adherence, and long-term efficiency. Whether you need a system for flour dust, grain dust, or general industrial use, selecting the right solution provides lasting benefits. With proper maintenance and up-to-date features, businesses can stay compliant and create safer, cleaner working environments.

Safe Pain Relief Options For Seniors Balancing Effectiveness And Side Effects

Choosing the Right Retirement Advisor: Your Guide to Financial Security

Rolling back the clock on addiction treatment will cost even more lives

5 Creative Ways To Use Photo Prints Beyond The Frame For Home And Gifts

Powering Your Home with Sunshine How Clean Energy is Slashing Electric Bills Nationwide

Finding the Best Hearing Aid for Seniors

Powering Your Home with Sunshine How Clean Energy is Slashing Electric Bills Nationwide

5 Essential Pharmaceutical Devices Every American Household Should Have

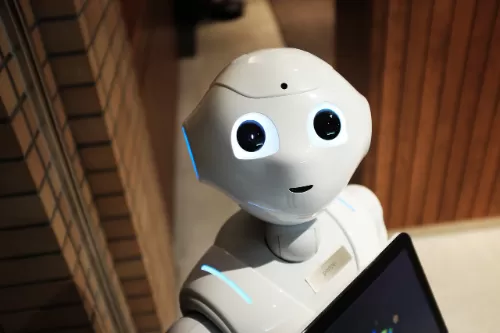

Robots with Empathy Can Machines Really Understand Feelings

UK food bank charity reports record take-up amid cost of living crisis